We are reader supported. When you purchase through links on our site, we may earn an affiliate commission. Also, as an Amazon affiliate, we earn from qualifying purchases.

When a power filter stops working, fish and beneficial bacteria lose support fast. Water can turn toxic within hours. You need a calm, clear plan that protects your fish, preserves your biological filter, and brings your system back online without causing a crash. This guide gives you step by step actions, timelines you can trust, and prevention strategies so you are ready next time.

First actions in the first 5 minutes

Act quickly to protect life support. Your two priorities are oxygen and bacteria. Keep fish breathing and keep your bio media alive. Everything else comes after that.

Keep beneficial bacteria alive

Beneficial bacteria live on your filter media. They need oxygenated water to survive. If the filter stops, flow and oxygen drop. Do not let filter media dry out. Do not rinse it under tap water. Keep it submerged in tank water with movement. If the filter is not running, remove the media baskets or sponges and place them in a bucket filled with tank water. Add an airstone or gently stir the water every few minutes to keep oxygen moving. At room temperature, submerged media with aeration can stay viable for several hours. Without aeration, bacteria start to die back within one to two hours. Keep the media warm and wet. Cold or dry media dies faster.

Keep fish oxygenated

When flow stops, gas exchange slows and oxygen can dip. Increase surface agitation right away. Add an air pump with an airstone if you have one. Lower the water level by one to two centimeters to let your return or any powerhead break the surface, but only if it is safe and you still have heating coverage. If you have no air pump, manually agitate the surface by gently scooping and pouring tank water for a few minutes at a time until you solve the filter issue. Reduce lights to lower plant night respiration stress. Keep the lid cracked if condensation reduces gas exchange, while preventing fish from jumping.

Quick checks before you disassemble anything

Many filter failures are simple. Check the basics before pulling the unit apart. This can save your bacteria and your time.

Confirm power supply

Check that the power strip is on and the outlet works. Plug in another device like a phone charger or light to confirm. Reset any ground fault outlets. Make sure the filter plug is fully seated. Inspect the cord for damage, heat, or water. Ensure a drip loop is present so water did not run into the outlet.

Re-prime the unit and clear airlocks

Loss of siphon or an airlock can stop flow. For hang on back filters, fill the filter box completely with tank water, then plug it in. For canister filters, follow the priming procedure. Use the primer pump, fill the canister with water, and ensure the intake and output hoses are full with no trapped air. For internal filters, ensure the pump is fully submerged and not sucking air at the surface. An airlocked impeller will hum but not spin.

Clear intake obstructions

Inspect the intake strainer and tube for plant matter, snails, or debris. Clogs can starve the pump and burn the motor. Remove buildup by swishing parts in a bucket of tank water. Do not use soap. Check the intake hose for kinks or collapsed sections. Confirm no media has shifted into the impeller area.

Reduce media clogging

Fine mechanical media can pack tight and block flow. If water is backing up or bypassing, remove the finest pad temporarily. Rinse mechanical media in a bucket of tank water to restore flow. Keep biological media wet and handle it minimally. The goal is to open the pathway for water without stripping bacteria.

Safe handling of filter media

Your bacteria handle ammonia and nitrite. Preserve them. How you manage the media decides whether your tank stays stable or cycles again.

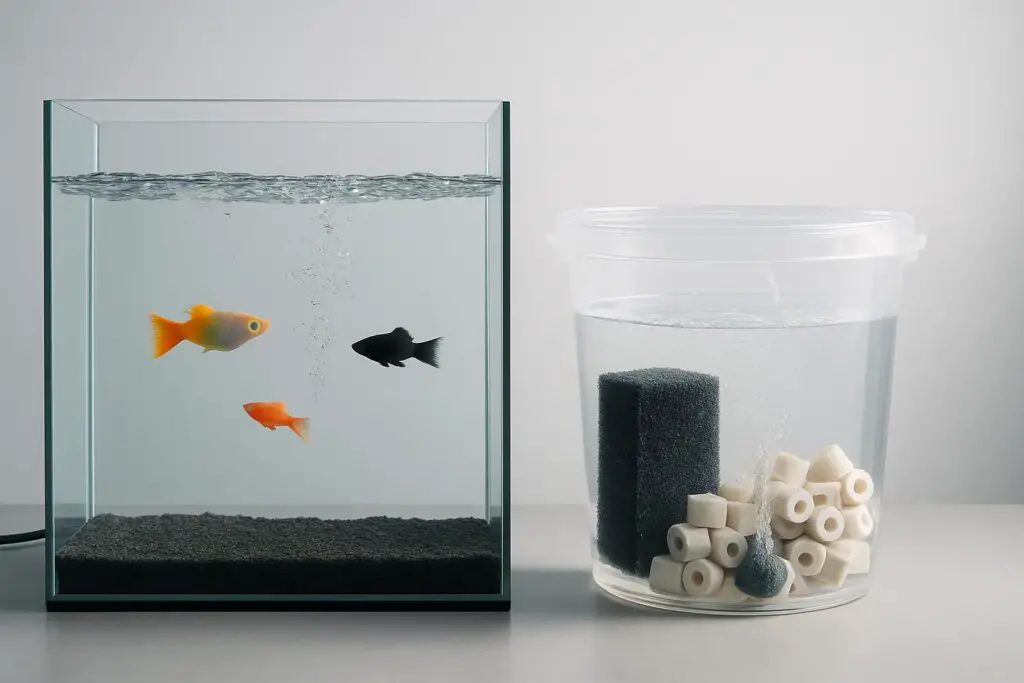

What to do with wet media during downtime

Keep media in tank water and keep it oxygenated. Place sponges, ceramic rings, and bio balls in a bucket of tank water with an airstone. Keep them at normal tank temperature. If you cannot aerate, stir the water gently every 10 to 15 minutes to refresh oxygen. Avoid sealing media in a closed container with no air. Anaerobic conditions can develop and create hydrogen sulfide. If downtime exceeds four to six hours, expect some die-off. Prepare for a controlled response with testing and water changes when you restart.

When to discard media and when to save it

Do not discard biological media unless it smells of rot or sulfur after a long outage and cannot be rinsed clean in tank water. If media went dry, some bacteria died but a fraction may survive. Reuse it with seeding support rather than starting from zero. Discard only carbon or chemical resins that sat stagnant for more than a day, as they can release captured compounds. Replace filter floss that is slimy and collapsing, but keep a small piece to seed the new floss if it does not smell foul.

Restarting by filter type

Each design has common failure points. Use steps that match your model for a smoother restart.

Hang on back filters

Unplug the unit. Remove the intake tube and strainer and rinse in tank water. Remove impeller cover, pull out the impeller and shaft, and wipe away slime and grit. Swish the impeller in tank water. Clean the impeller well with a soft brush or cotton swab. Reassemble. Fill the filter box completely with tank water. Ensure media is seated so water can flow freely. Prime the intake tube by filling it with water or by letting the box water draw it. Plug in. If the impeller hums but does not spin, unplug, spin the impeller gently with a clean finger, reassemble, and try again. If it still fails, the motor may be failing or there is an air pocket. Tilt the unit slightly to release trapped air.

Canister filters

Unplug the unit and close the intake and output valves. Move the canister to a towel-lined area. Open and remove media baskets, keeping bio media submerged in tank water. Rinse sponges and coarse pads in tank water to remove sludge. Do not overclean ceramic rings or bio balls. Remove the impeller cover. Clean the impeller, shaft, and well. Inspect the ceramic shaft for cracks. Reassemble the motor head with a light film of water on the seal. Pack media in correct order: coarse mechanical first, fine mechanical next, biological last, chemical media after biological if used. Fill the canister body with tank water. Reattach hoses, open valves, and prime until hoses are full. Plug in and watch for bubbles purging. If microbubbles persist, gently rock the canister to release trapped air. Check for leaks at the head seal and valve block.

Internal power filters

Unplug and remove the unit. Open the intake grid and impeller cover. Clean the impeller and well. Rinse sponge or cartridge in tank water. Reassemble and fully submerge. Ensure the waterline is above the minimum mark. Prime by tilting to release air pockets. Plug in while the unit is underwater to prevent dry running.

If the motor is dead

If the motor is silent and does not vibrate after cleaning and priming, it may have failed. You still need biological filtration and flow while you replace it.

Interim filtration to keep the tank safe

Run a sponge filter with an air pump. A double-sponge filter can handle a surprising load and keeps bacteria supplied with oxygen. If you do not have one, place your existing bio media in a mesh bag in the tank near an airstone or powerhead to keep water moving through it. Use any spare internal pump or small powerhead to circulate water and create surface agitation. Reduce feeding to lower waste. Perform controlled water changes, not massive swings.

Bacterial reseeding plan

Install a new filter as soon as you can. Move the old bio media into the new filter to seed it. If the old media does not fit, place it in the filter intake area or in the path of strongest flow until the new media colonizes. Consider bottled nitrifying bacteria from a trusted brand to bridge the gap. Shake well and follow the dosing schedule. Monitor ammonia and nitrite daily until readings are stable at zero.

Managing water quality while the filter is down

Your tank can stay safe with careful testing and measured responses. Avoid panic changes that shock fish.

Emergency water changes

If ammonia or nitrite rises above 0.25 ppm, do a 25 to 50 percent water change with temperature-matched, dechlorinated water. Use smaller, more frequent changes rather than one large change that swings parameters. Vacuum detritus lightly to remove waste without stripping too much bacteria from the substrate.

Testing schedule and action thresholds

Test ammonia and nitrite every 12 to 24 hours for the first three days after an outage or restart. Ammonia should read zero. Any reading above 0.25 ppm needs action. Nitrite should read zero. Above 0.25 ppm, increase aeration and perform a water change. Nitrate will likely rise. Keep it under 40 ppm for most community fish, lower for sensitive species. If pH drops sharply after the outage, perform partial changes to stabilize. Keep temperature steady within one degree to avoid compounding stress.

Detoxifiers and how to use them

Use a conditioner that detoxifies ammonia and nitrite temporarily while your biofilter recovers. Dose according to the label and redose as directed after water changes. Detoxifiers do not remove ammonia. They bind it so it is less toxic for 24 to 48 hours. Keep testing because many kits still register bound ammonia. Focus on trends and fish behavior along with the numbers.

After restart issues

Many filters restart with side effects. Address them early to avoid another failure.

Rattling or grinding noise

Noise often comes from a dirty or damaged impeller, mis-seated shaft, or trapped air. Recheck impeller seating, remove any sand grains, and purge air by tilting. Replace worn impellers and shafts if noise continues.

Leaks

For canisters, inspect the main seal and valve block o-rings. Reseat or replace o-rings and lubricate with aquarium-safe silicone grease. Ensure latches are fully engaged and baskets are aligned so the head sits flush. For hang on back filters, check the case for cracks and for siphon tube leaks at joints.

Low flow

Low flow after restart points to clogged media, air in the system, or a weak motor. Remove or rinse the finest pad. Ensure hoses are free of kinks. Confirm the impeller spins freely. If flow remains weak, replace the impeller and check voltage. Reduce head height on canisters by lowering placement and shortening hoses if possible.

Preventing future failures

Filters fail less with simple habits and backup plans. Build redundancy and keep maintenance light but regular.

Maintenance that protects bacteria and the motor

Rinse mechanical media in old tank water every two to four weeks, or sooner if flow drops. Clean the impeller and well every one to two months. Swish biological media gently in tank water only when flow is restricted by slime, not on a fixed schedule. Replace carbon monthly if you use it. Replace floss when it collapses. Do not replace all media at once. Stagger changes by weeks to preserve colonies. Keep the intake strainer clear. Position the intake away from sand or fine substrate to avoid grit wear.

Power outage planning

Use a battery air pump that turns on when power fails. Keep spare batteries. A small uninterruptible power supply can run an air pump for many hours and a small internal filter for a shorter time. For long outages, a generator keeps heaters and filters running. Store water conditioner and test kits on hand. Have a clean bucket, spare airline, and a seeded sponge filter ready at all times. A mature sponge filter kept running in the tank or sump is cheap insurance.

Redundancy and system design

Run two filters sized for the tank rather than one large unit. If one fails, the other keeps the tank stable. Pair a hang on back or canister with a sponge filter. Place prefilters on intakes to prevent clogging and to protect fry and shrimp. Use a ground fault circuit interrupter outlet and make drip loops on all cords to reduce electrical hazards. Keep filters accessible for fast service. Avoid overcrowded media stacks that starve flow.

Stocking and feeding adjustments

Heavily stocked tanks crash faster during filter failures. Stock conservatively. Feed lightly and consistently. During any filtration issue, cut feeding by half until parameters are stable. Offer small meals that are consumed within a minute. Remove uneaten food at once.

Common mistakes to avoid

Do not rinse bio media under tap water. Chlorine and chloramine kill bacteria. Always use tank water for cleaning media. Do not leave media dry on a towel. It will die. Do not run a filter dry to test it. Impellers overheat fast without water. Do not replace all media at one time. This resets the cycle. Do not do a massive full tank water change after an outage unless ammonia is extreme. Large swings can stress or kill fish. Do not ignore a humming motor. That sound often means a jammed impeller or airlock that can burn the motor.

Special notes by tank type

Planted tanks can handle small ammonia spikes better due to plant uptake, but plants also consume oxygen at night. Keep aeration strong during outages. Shrimp and small invertebrates are sensitive to copper in some water supplies, so always dechlorinate and avoid new copper-based treatments during stress. Goldfish and cichlids produce heavy waste. Their tanks need extra aeration and faster response to rising ammonia. Marine tanks and reef systems rely on larger biofiltration and protein skimming. During power issues, prioritize aeration and circulation pumps to protect oxygen and pH, and keep live rock submerged and oxygenated.

Troubleshooting quick guide

If the filter does not power on, test the outlet, cord, and power switch. If it hums but does not move water, clean and reseat the impeller and prime fully to remove air. If flow is weak, clear intake, rinse mechanical media, and check hoses. If the unit stops after a few minutes, look for thermal shutdown due to a jam or clogged media. If water bypasses media, reseat baskets or cartridges and avoid overpacking fine floss. If the filter restarts but water parameters spike, your bacteria population took a hit; seed with established media or bacteria product, increase aeration, and start a testing and water change plan.

Realistic timelines for bacteria survival

At normal room temperature, submerged media with good aeration can hold most bacteria for six to eight hours. Submerged media without aeration starts losing efficiency in one to two hours, with noticeable die-off by four hours. Wet but not submerged media declines quickly and can smell foul within hours. Dry media loses most bacteria within an hour. Heat and lack of oxygen accelerate loss. Cold slows activity but can still cause die-off if oxygen is limited. Plan responses around these timelines. Aeration buys time. Heat stability reduces stress. Fast restart preserves your cycle.

What to keep in your emergency kit

Keep a battery air pump with spare batteries, an airstone and airline, a pre-seeded sponge filter, a water conditioner that detoxifies ammonia and nitrite, test kits for ammonia, nitrite, nitrate, and pH, a clean bucket labeled for aquarium use, spare impeller and shaft for your filter, silicone grease for o-rings, and extra coarse sponge or prefilter material. With these on hand, most failures become minor events.

How to verify success after recovery

Confirm steady zero ammonia and zero nitrite for one week. Flow should be strong and consistent. Fish should breathe normally and show normal appetite. The filter should start cleanly after a brief unplug test. Noise should be minimal. If all checks are positive, resume normal feeding. If any metric is off, investigate and correct before returning to full feeding or stocking.

Frequently asked questions

How long can fish live without the power filter running

Fish can live without the filter motor if oxygenation is maintained and waste is controlled. With strong aeration and light feeding, many community tanks can remain stable for a day or more. Without aeration, oxygen can fall within minutes to hours depending on stocking and temperature.

Is it safe to run only an air-driven sponge filter

Yes. A properly sized sponge filter provides biological filtration and aeration. Many aquarists run sponge filters long term. Keep it clean by squeezing in tank water during water changes.

Should I clean everything after the filter stops

No. Only clean what is blocking flow. Preserve biological media. Overcleaning can force a new cycle. Target the impeller, intake, and mechanical pads.

Do I need bottled bacteria

They help after outages or media loss. Choose a reputable brand with live nitrifiers. Use them to seed new filters or support recovery, alongside testing and water changes.

What if I smell rotten eggs from the filter

That is a sign of anaerobic growth. Do not dump the water back into the tank. Discard the stagnant water, rinse media in fresh dechlorinated tank-temperature water, and run heavy aeration. Consider partial replacement of media and add bottled bacteria. Monitor closely.

Conclusion

A failed power filter is stressful, but a focused response protects your fish and your cycle. Keep media wet and oxygenated, keep fish breathing, clear simple faults, and restart methodically. If the motor fails, run a sponge filter, seed the new unit, and manage water quality with testing and measured changes. Build redundancy with backup aeration and a pre-seeded sponge filter. Maintain the impeller and mechanical media so flow stays strong. With preparation and a clear plan, a filter outage becomes a brief inconvenience rather than a tank emergency.